Saving Up on Resources with the Use of Sludge Briquetter

Makers of certain products such as heavy machines, gear grinders, wind turbines, bearings, air coolants and other products made for commercial use generally are challenged on how to dispose of grinding sludge that is produced during the process of making them. This also holds true of the large volumes of this by-product processed when grinding these machines and devices.

Makers of certain products such as heavy machines, gear grinders, wind turbines, bearings, air coolants and other products made for commercial use generally are challenged on how to dispose of grinding sludge that is produced during the process of making them. This also holds true of the large volumes of this by-product processed when grinding these machines and devices.

Grinding is an essential factor needed to be done in order to achieve the highest precision and finishing for many final products. It is also necessary for this to create a sludge which is generally not needed in the other processes, therefore the need to dispose them. This often has very tiny metal chips and grinding oil. Disposing them usually has to put out certain investments and high prices because of their effects to the environment. Several manufacturers have long treated this issue for several years.

The Situation

In several cases, the disposal of the grinding sludge has proven to consume too much money and time. For the manufacturers to remain accurate in their work, they use significant amounts of oils and fluids but some of these are considered as waste. Many companies today that produce sludge have fortunately found a very effective and highly sustainable cleaner and function in order to dispose of these by-products. Aside from these qualities, the new way is also known to be cost-efficient and can recover even some of the items trapped inside the matter. This is possible through the method that uses a sludge briquetter.

The Method

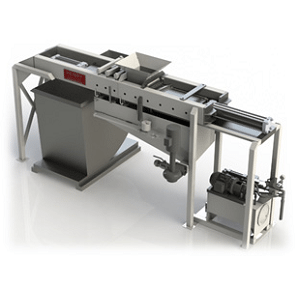

The method is also known as sludge waste disposal, and in the recent years, it has gained popularity in Europe and in North America. Basically, the process of briquetting pertains to the compression of materials such as metal grinding chips into manageable and compact blocks shaped like a cylinder. These blocks are called briquettes. They have densities and values for resale that can match those of other solid metals. This means that aside from a smart way to dispose the sludge, they can also turn out great profits. When this method is applied, the oil can be recovered and reused in a good way.

Furthermore, briquetting also boosts the industry by adding value to the aspect of the waste disposal. It requires some investment to have the materials though, but the use of a sludge briquetter has been known to reduce energy costs, labor costs and transportation costs while adding revenue to the company as well.

On the other hand, companies that do not use these briquetters are often met with a by-product that needs a high amount of money to be disposed of. They are added to landfills and never recycled. But remember that the sludge is characterized by its significant weight and is usually challenging to bring to other places.

BARNES INTL, INC.

814 Chestnut Street

P.O. Box 1203

Rockford, IL 61105-1203

HENRY FILTERS

555 Van Camp Road

Bowling Green, OH 43402