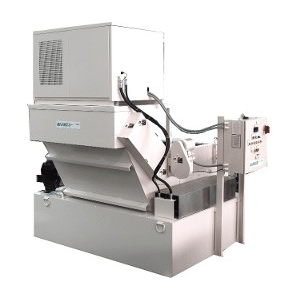

Description

Performance Enhancing Features

- Standard Sizes are 500 GPM / 1892 LPM, 1000 GPM / 3785 LPM, 1500 GPM / 5678 LPM, 2000 GPM / 7570 LPM, 2500 GPM / 9463 LPM, 3000 GPM / 11356 LPM.

- Primary Filtration is performed by rotating drums with a heavy-duty replaceable permanent media screen.

- Optional Secondary magnetic filter allows the separation of cast iron and aluminum fines into two streams.

- Side Stream at 15 Percent is directed to a small, vacuum type, disposable media filter to trap and remove the micro fines generated by the machining process.

- Full Flow Secondary Filtration Consisting of automatic backflushing stainless steel elements. (Optional)

- Equipment has a robust automotive-based design and is maintenance friendly to give years of trouble-free service

Coolant Vacuum Polishing Filter

- 10-20% Sidestream Flow Cleaned to 10 Micron

- Minimizes Use of Filtration Media

- Tramp Oil Removed with Spent Media

- Spent Media Automatically Re-rolled at Discharge End

Full Flow Automatic Backflushing Sentinel Filters

- Full Flow Protection to Machines

- 30 Micron Permanent Media

- Pressurized Backflush for Cleaning

- Backflushes to Polishing Filter