Description

Automated Filtration

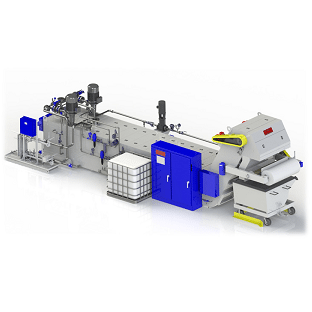

Overview

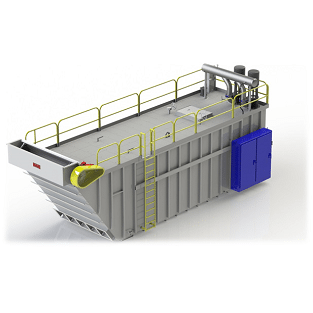

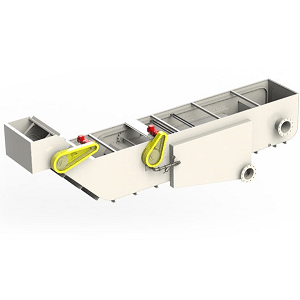

Henry SEP offers conveyor-aided filtration suitable for a range of material processing applications. The regulated flow of coolant over adjustable overflow weirs allows for the settling of fine particles, and clean coolant is sent back to process. Conveyorization of settled chips and fines prevents contaminant buildup and coolant degradation.

Features

- Automatic operation

- No disposable media required

- Settles and removes chips and fines

- Removes floating debris

- Modular system permits capacities to 10,000 gallons per minute

- Used often on cast iron, glass, and ceramics

- Easy adjustment-minimal maintenance

System Benefits

Operation

- Coolant enters the skimmer or inlet at the rear. The optional skimmer removes grease, graphite, and tramp oil.

- Flow passes under the divider and up towards the multiple overflow weirs.

- Settled chips are removed from the bottom and out the discharge ramp to tote box via the conveyor.

- Velocity over the weirs is reduced to approximately one vertical foot per minute rise, which eliminates crosscurrents and permits settling of fine particles.

- Coolant flows over adjustable weirs to clean tank, where it is pumped back to process by clean coolant pumps.

- A clean tank is conveyorized to prevent the buildup of fines over a long period of time, which would result in coolant degradation.

The system is ideal for applications that might blind over a filter barrier, such as ceramics, glass, or flocculated fluids, or with particularly heavy materials, such as cast iron, nodular iron, or uranium.